Our internal laboratory thoroughly analyzes every incoming lot of compound. Laboratory tests focusing on hardness, density, elongation, braking strength, racking strength, compression set and others are repeated constantly on our raw material.

Simulated wear tests of every element and at any temperature may be performed upon request from the customer in case of very specific applications. Moreover, Falga cooperates with the most authoritative laboratories and research centers on elastomeric material in order to develop new compounds featuring better and more performing characteristics.

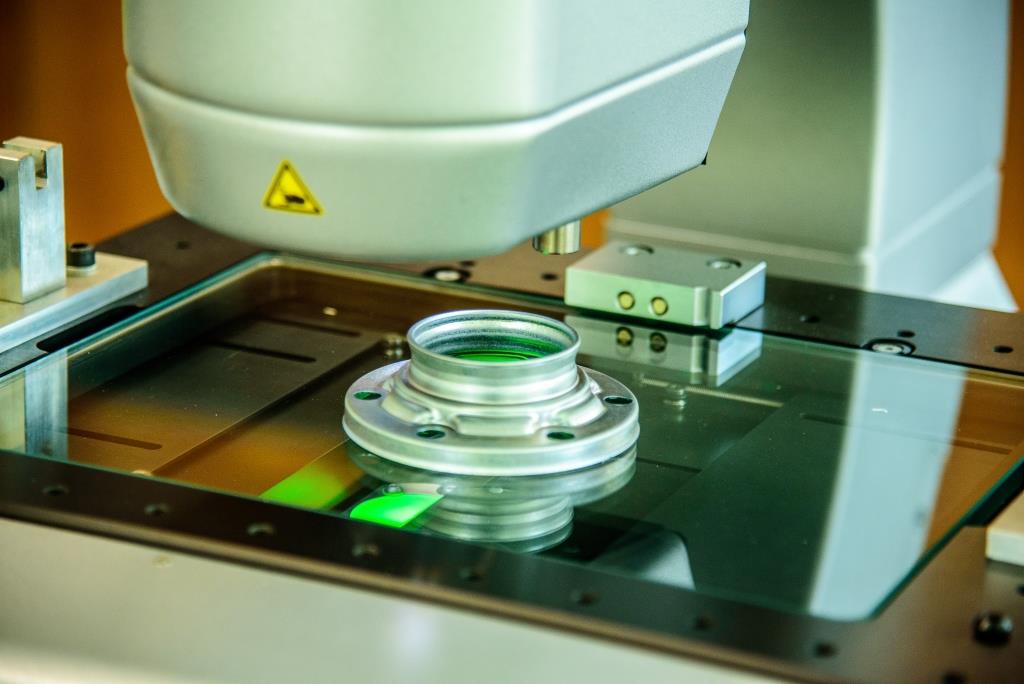

Moreover we engineered a test machine for the measurement and for the analysis concerning the ratio between deformation load and axial compression length of the CV Boots. It allows to check the correct ratio between the two a.m. values in order to eliminate, at the engineering and industrialization stages, many of the early wear defects arising during use.Due to an incorrect sizing of the thickness of the turns the CV Boot may be too rigid or too flexible, or may not be in tune with the correct deformation phase.

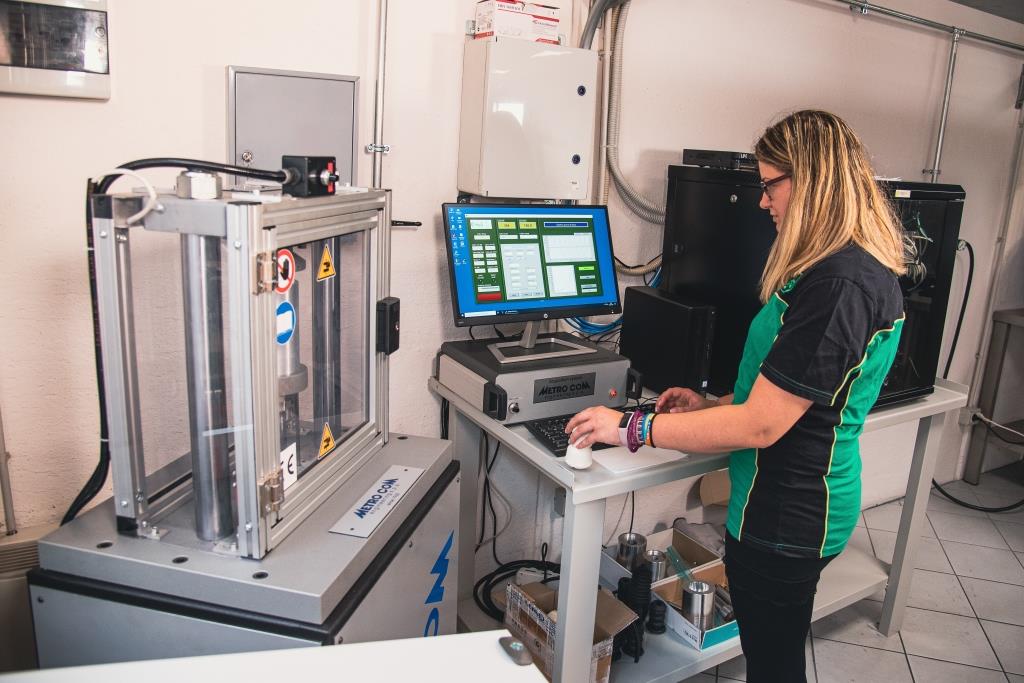

Since June 2019 the Falga R&D Laboratory has been enhanced by a new MDR2000 Rheometer of the latest generation for the development and for the testing on the compounds used in production.

Alpha Technologies, a leader in the design and construction of these equipments, supported us in its selection and implementation.

The Rheometer has been installed side by side to the Mooney Viscometer, already in use, for an ever greater guarantee of quality of our products.